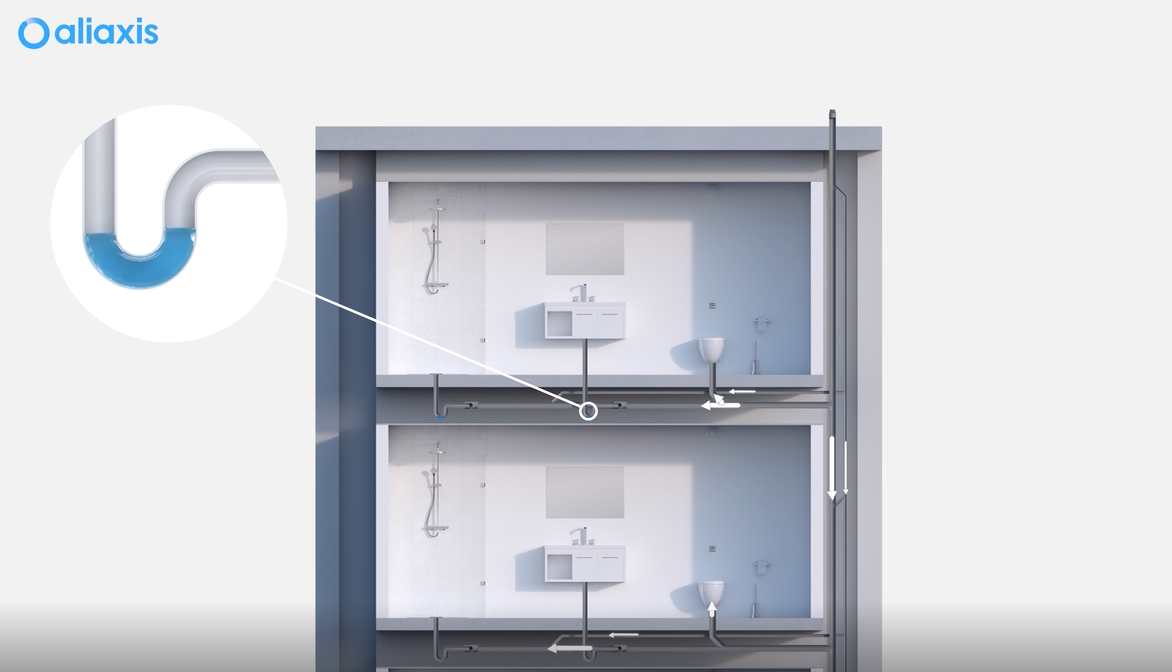

Plumbing regulations call for the water trap seal on sanitary fixtures to be maintained at all times. This is typically accomplished by introducing atmospheric air into the plumbing drainage system via a separate smaller vent pipe going through the roof. But there are limitations to venting with pipes in the conventional way.

Aliaxis has developed innovative single stack solutions that eliminate the need for a separated vent pipe, allowing customers to save space, costs and installation time and ensure better system performance.

These single stack solutions are especially helpful in solving design challenges for taller buildings, open or complex buildings, green buildings, or modular buildings, but they also provide benefits for middle-rise buildings. Challenges that can be addressed with a single stack solution include no possible roof penetration, limited vertical shaft space, complex shaft structure, a need for a secondary system for recycled water, or other circumstances.

Our single stack solutions are of two types:

- Single stack system (innovative passive venting). The single stack system with stack aerator limits pressure transients, protecting traps seals up to a certain water flow.

- The P.A.P.A. ( Positive Air Pressure Attenuator) (active venting). The P.A.P.A. (Positive Air Pressure Attenuator) system gets rid of the pressure transients as quickly as possible to avoid water trap seals breach, with no limitation of height or water flow rate. This system is used in new buildings as well as in existing buildings as a problem-solver.

A single stack system with stack aerators is always composed of three elements:

- A stack aerator on each floor

- A pressure relief line at the base of the stack

- Venting through the roof

The stack aerator will limit the generation of negative transients through its design which reduces water velocity and protects the core of air. It is composed of:

- An offset chamber where flow from upper floors enters the stack aerator fitting and offsets around the horizontal branch inlet. This chamber has specific angles to ensure performance, by reducing the flow velocity and breaking up any partial hydraulic plug formation (blockage of core of air), making the flow cling to the interior surface of the pipe and leaving the centre area open for air.

- A mixing chamber for horizontal flow to prevent horizontal branch discharge from blocking the stack’s cross-sectional area and at the same time prevent stack wastewater from entering the horizontal line. The horizontal entry mixes gently with the diverted stack flow and it also allows for multiple horizontal connections.

- The vent aperture at the top of the mixing chamber which provides the venting action between the branches and stack. It will allow horizontal lines to be ventilated at peak flow, preventing any blockage.

The pressure relief line will be installed at the base of the stack and wherever the stack requires a horizontal offset. It aims to avoid positive pressure transients created by the transition of vertical flow to horizontal flow, a phenomenon referred to as hydraulic jump.

The venting through the roof will secure ventilation of the system, keeping the pressures (already limited by the stack aerator design and by the pressure relief line) in the boundaries to protect trap seals.

Using the single stack system with stack aerators removes the vent pipes and provides a cost-effective solution, saving valuable commercial building space, material, fire compartmentation and installation costs, combined with a strong performance, reaching better capacity compared to the conventional (and more expensive) options.

The P.A.P.A. system is an active system providing relief at the Point Of Need (PON) by removing or attenuating an incoming transient that, if left, would lead to trap seal depletion. The system is composed of Air Admittance Valves (AAVs), responding to negative pressure transients, and P.A.P.A.s responding to positive pressure transients. This system was developed starting from the observation that the most efficient way of dealing with the call for increased or decreased airflow (pressure transients) is to answer it as quickly as possible. This is achieved by placing AAVs and the P.A.P.A. onto the standard pipes of the system to limit the surge pressures adjacent to the traps by reducing the rate of local changes in flow conditions. The placement of the AAVs and the P.A.P.A must be positioned between the source of the transient and the base of the stack; offsets are typical points to generate positive transients. The pipe calculations for loadings and gradients do not change when installing active drainage ventilation (so BS EN12056 can still be used for the sizing of the system).

- Negative pressure (transients) are dealt with through the introduction of local airflow using AAVs on the branches. Air is allowed in through the AAV as required, which then seals tight to prevent sewer gases from leaking out into the habitable space. This has the benefit of eliminating the vent pipe network and the roof penetrations, reduces the space required, and greatly simplifies the design of a large plumbing drainage system.

- Positive pressure (transients) are absorbed by the P.A.P.A., slowing them down from the speed of sound (320m/s) to a harmless 12m/s, to then release them back into the system to naturally dissipate. The P.A.P.A. must be located as close to the source as possible. So in the case of a transient produced at the base of a stack, relief is needed at the bottom, not at the top. In laboratory tests P.A.P.A.s have been shown to reduce the magnitude of a positive air pressure transient by up to 90%. The device allows for effective diversion of the airflow and its gradual deceleration.

Active venting should be considered functionally superior to conventional passive venting:

- The removal of long and possibly convoluted vent connections to atmosphere reduces the time taken before local relief can be applied – allowing the pressures to be balanced more quickly with active venting.

- Local suppression prevents transient propagation throughout the network prior to relief – removing the risk of the siphonage of multiple traps.

With conventional passive venting, reliance on roof-penetrating open terminations allows transients to travel the whole system prior to any remedial action which increases the risk of trap seals depletion.

The P.A.P.A. system improves the performance of drainage systems, eliminates any transient pressure problems, saves space, reduces labour, and offers savings on material, installation and maintenance costs. By fully protecting trap seals, it reduces the risks of diseases or germs being transmitted through the drainage system (e.g. SARS), and odours. This solution provides greater freedom of design to the architect by reducing the area needed for the shaft, and avoids having to go through the roof. Finally, it requires less pipes so reduces fire propagation concerns.